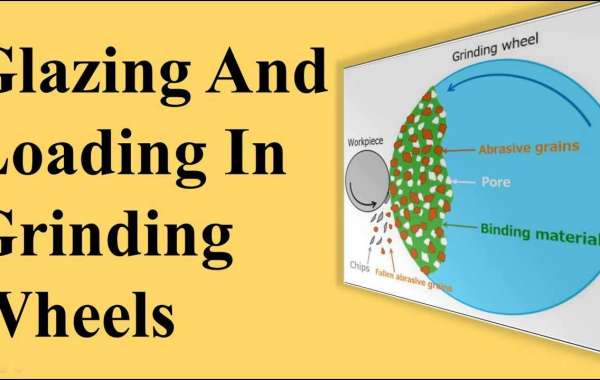

Grinding wheels are essential tools in many industries for cutting, shaping, and finishing various materials. However, their efficiency and effectiveness can be compromised by two common problems: glazing and loading. In this blog post, we'll take a closer look at what these issues are, their causes, and how to prevent them.

Glazing occurs when the abrasive particles on the surface of the grinding wheel become dull or clogged, resulting in reduced cutting action and heat buildup. It's a common problem when grinding hard materials such as steel or ceramics. One of the main causes of glazing is using a grinding wheel that is too hard for the material being ground. Another reason could be that the grinding wheel's surface is loaded with debris from previous grinding operations, causing the abrasive particles to become ineffective.

To prevent glazing, use a grinding wheel that matches the hardness of the material being ground. Also, ensure that the grinding wheel is clean and free of debris before use. Dressing the wheel regularly with a dressing stick or diamond tool can help expose fresh abrasive particles on the surface.

Loading occurs when the spaces between the abrasive particles on the grinding wheel become filled with the material being ground or debris from the grinding process. It results in reduced cutting action, increased heat buildup, and can lead to glazing. Loading is more common when grinding soft materials such as aluminum or copper.

To prevent loading, use a grinding wheel with a softer bond that allows the abrasive particles to break down and self-sharpen. Use a coolant or lubricant to flush away debris and prevent it from clogging the spaces between the abrasive particles. Dressing the wheel regularly also helps to prevent loading.

In conclusion, glazing and loading in grinding wheel are common problems that can affect the efficiency and effectiveness of grinding wheels. By understanding their causes and implementing preventive measures, such as selecting the appropriate grinding wheel, keeping it clean and dressing it regularly, and using coolants or lubricants, you can avoid these problems and ensure that your grinding operations run smoothly and efficiently.